At Indepak, we know that when it comes to consumer packaged goods, creating an aesthetically pleasing design that showcases one’s product can be the difference between success and failure.

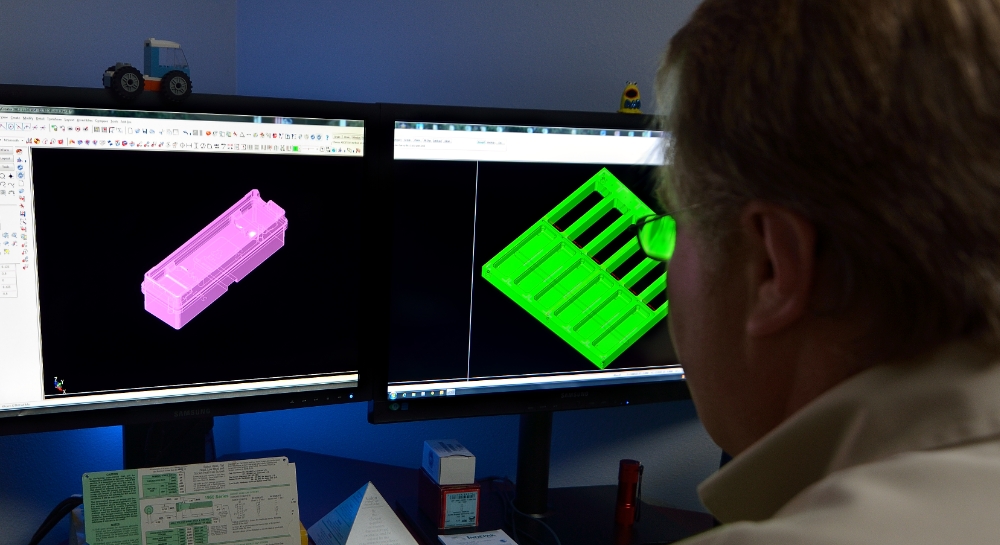

Design & Prototyping

When you work with Indepak, you’ll have a partner that can walk you through the entire design, development and sampling process to ensure you will have a package that:

- Protects your product

- Secures product and deters theft

- Stands out on the store shelf

Plus, with our extensive in-house capabilities, we can ensure quick “Speed to Market” and even share ideas for how to efficiently put products in the package.

Collaboration

We have extensive experience collaborating with other packaging suppliers including printers, box manufacturers, sealing equipment companies and automation integrators. This experience helps us ensure that the thermoformed components we supply will integrate with the entire package and can be processed quickly and efficiently.

Material Specifying & Sustainability

Our team not only has the expertise to develop an attractive and functional package, but our extensive knowledge of materials can also play an integral role in the success of your package design.

We can form a variety of post-consumer, recycled-grade materials for those looking to achieve sustainability goals and have extensive experience with food-grade materials, ESD and conductive materials, and more.

Common Types of Retail Packaging

Packaging Trays

Clamshells

Blisters

Containers

Added Functionality

While the role of many thermoformed packages is limited to “packaging,” our design team has had experience creating solutions that go beyond this typical requirement. For instance, we designed a trifold clamshell that doubles as a tape dispenser, we created a clear lid that doubles as a dry erase board and many of our packages retain their use as a storage container even after they have left the store shelf.

Tape Dispenser

Dry Erase Board