Every industry has unique packaging needs. For instance, when we design packaging for food items or pharmaceuticals, ensuring safety is always crucial. When it comes to packaging for electronics, it’s crucial that we develop packages that protect your static-sensitive products.

Here’s a quick overview of packaging for electronics and what Indepak can provide for you.

Electronic Packaging Materials

At Indepak, we use many rigid plastic materials suitable for packaging for electronics. Anti-static packaging is designed to prevent the build-up of static electricity, which can damage your product’s static-sensitive components. Conductive materials allow electrons to flow across your packaging, rather than building up, which prevents damage, and these materials also act as a shield against electromagnetic interference. Static-dissipative materials provide you with more electrical resistance than would anti-static package, but not as much resistance as conductive.

Indepak's Process

Our first step will be to learn about your product’s sensitivity and determine the level of protection you will need. After all, some products and components are more static-sensitive than others, so the first step is to meet with our design team so that they can gain a thorough understanding of your product and all of its components.

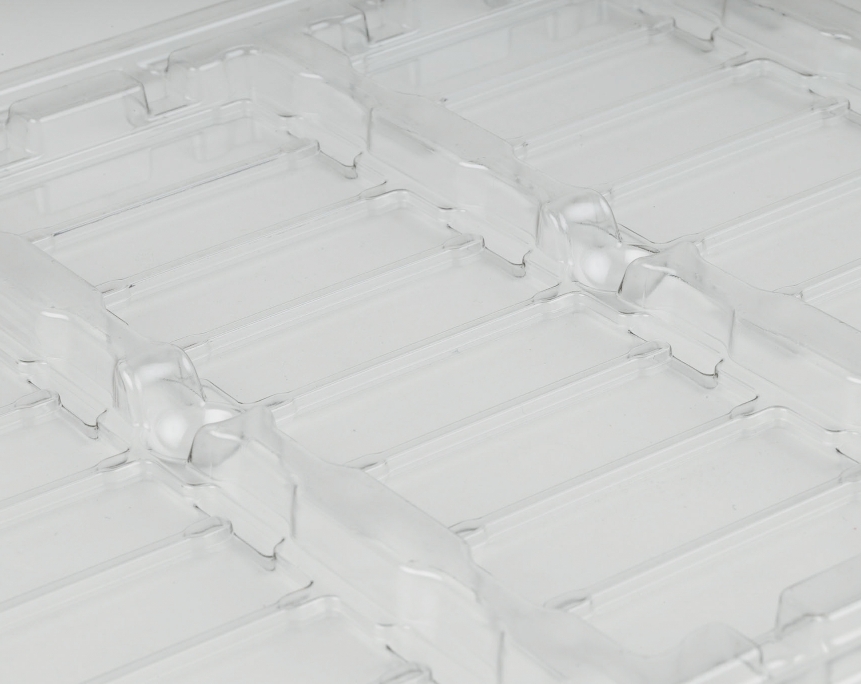

Packaging for electronics, often known either as anti-static packaging or ESD packaging, can be made in virtually any size and shape. Utilizing our thermoforming expertise we can transform a rigid sheet of thin-gauge thermoform plastic into just about anything you might need.

When we create packaging for electronics we work with a variety of dissipative and conductive materials to ensure that your static-sensitive materials are well-protected. We can design thermoformed trays to hold various components or design clamshell packaging to hold individual parts within a larger package. We also can create highly complex inserts, with specially designed cavities that will protect your product from static, as well as the jostling typically associated with product transportation.

Sustainability

These days most of our clients ask us about sustainability and virtually all of the materials we use are recyclable, and we can use post-consumer grade materials for your project, even when it comes to electronics packaging. Our design team also focuses on developing creative designs that reduce the amount of materials we need to use, thus reducing your packaging costs as well as increasing sustainability. This may reduce your shipping costs, as well, as smaller packaging may allow you to transport more units per shipment.

In the end, the most important aspect of designing packaging for electronics is to ensure that your products are protected on every level, from eliminating the potential for static damage to ensuring that products are safe during transport to ensuring that your packaging is tamper-resistant.